Technical information

In 2018, we received bid for BYD auto for induction pipe bending project, they want to expand their steel structure factory for hot pipe&tube bender industry, to get new increasing profit because the order for auto industry decrease recent year.

More than 20 suppliers participate in the bidding, after several months of technical document work, on line technical meeting, price discussing and factory visit, Duolin won the bid as No 1 finally, it’s our honor to serve the BYD company.

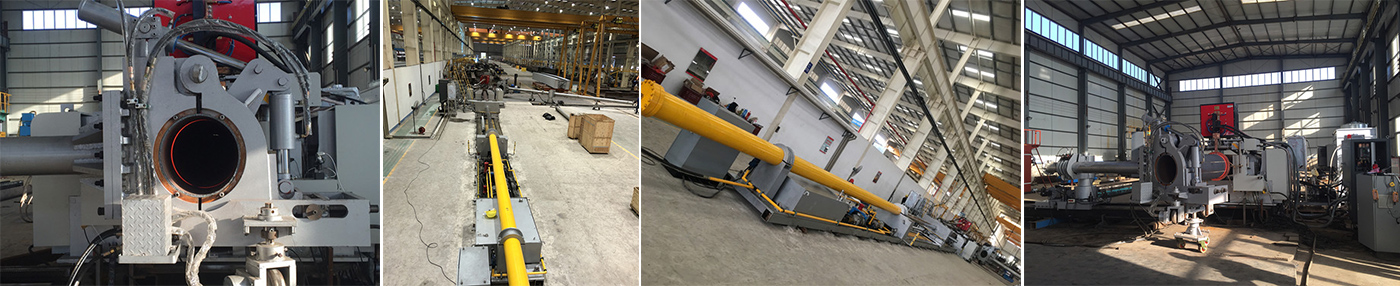

In June 2019, 350KW low frequency induction heating machine and hydraulic pipe bending machine finished the production and transport to BYD factory in Guangzhou, Duolin engineer team went to there for installation, including the water cooling path, electric connection, PLC and the complete bending system debugging, training for workers, machine operation and daily maintain….Until the bending system work normally for more than 1 week, good performance and long time stable work turn-key pipe induction preheating project for hot bends installed in BYD plant.

During these years,Duolin also help customer to make daily maintain and offering spare parts to repair bending production line.

Except the pipe heating for bending, Duolin team can offer pipe heating for coating,elbow making,expanding and suggest other machines need for complete production line.

Duolin your expert for induction heating solution, we will be here serve you when in need.