Series and Parallel medium frequency power supply difference

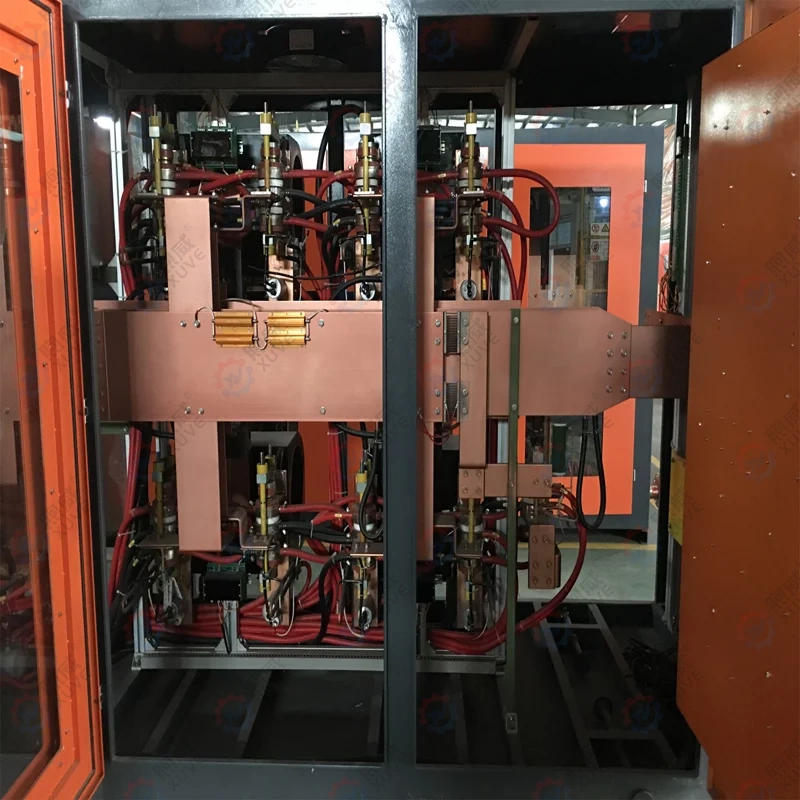

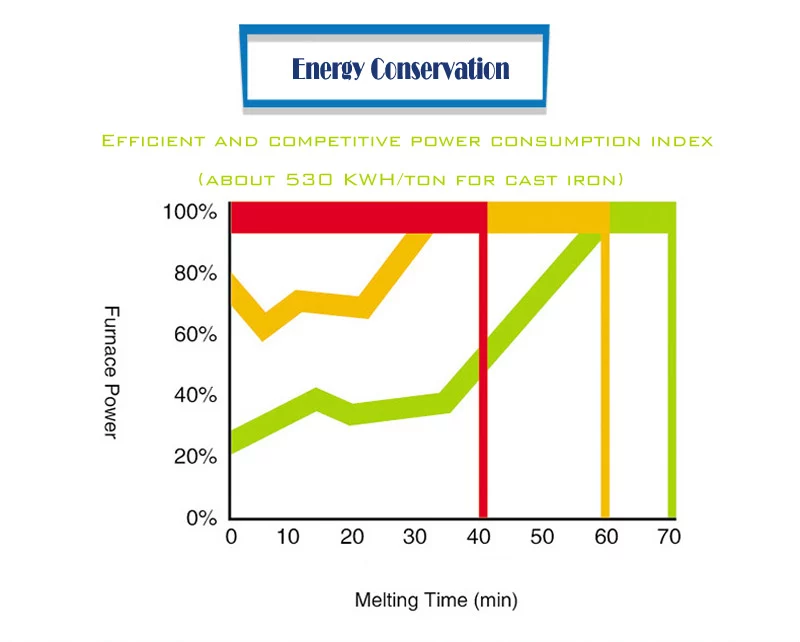

ZHENGZHOU KETCHAN’s medium frequency power supply adopts full-wave rectifier series power supply, in the whole working process, the rectifier is always in the fully open state (equivalent to diode rectifier), does not produce high harmonics, and has no pollution to the power grid. It does not affect the operation of the reactive power compensation capacitors in substations. Reach international harmonic current, voltage allowed value. Compared with ordinary parallel inverter power energy-saving about 20% (tons of molten iron power consumption of about 530 degrees).

KETCHAN’s parallel medium frequency power supply: One of the most widely used, inexpensive accessories medium frequency power supply in the last few decades. Disadvantages: high energy consumption, power consumption of about 700 degrees per ton of molten steel. DC voltage regulation is adopted to adjust the power, the power factor is lower than or equal to 0.90, and there is harmonic interference, which has varying degrees of influence on the operation of reactive compensation capacitors in a substation.

Steel shell melting furnace and Aluminum shell melting furnace difference

- Steel shell Melting Furnace body:

Using hydraulic station dump furnace device; High-quality steel structure welding, more safe, firm, durable; Magnetic yoke closed, covering an area of more than 65%. Compared with aluminum shell furnaces, energy consumption is nearly 5%, equipped with a leakproof furnace alarm device, can predict the furnace in advance and achieve the purpose of safe production. The medium frequency power supply steel shell furnace body is designed with two kinds of dust removal systems, a smoking hood and a smoking ring, which meet the requirements of environmental assessment. Users can choose the configuration according to their needs.

- Aluminum shell melting furnace body:

Reducer tilting furnace device; The furnace body is made of alloy aluminum foundry; Low price, easy maintenance, and convenient observation. The disadvantage is that efficiency and service life and safety are relatively low, and electromagnetic radiation without shielding. Because the aluminum shell furnace body has no smoking dust removal device, some local government departments have ordered the use of units to replace the aluminum shell furnace body with a steel shell furnace body.

What is the advantage of the KETCHAN medium frequency power supply?

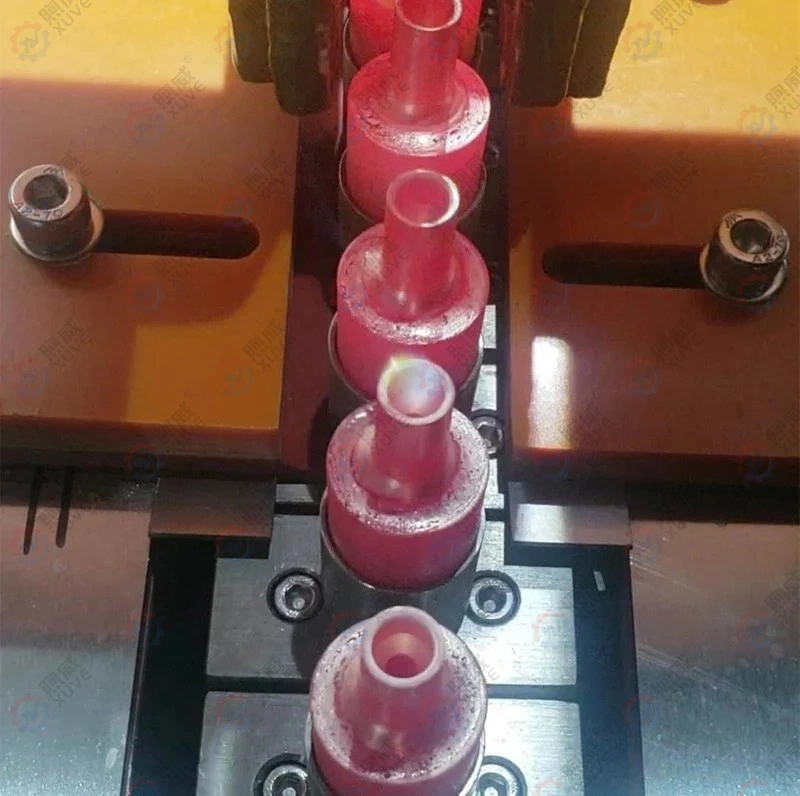

- Hig efficiency: Single furnace induction melting time can be the fastest ≤ 40 minutes! The power of the medium frequency power supply equipment is in the highest state (≥96).

- Energy-saving: Cast iron about 530 KWH/ton

- Harmonic: The full-wave rectifier series medium frequency power supply in a full – the open state does not produce high harmonic pollution.

- Induction coil: High-quality TU1 oxygen-free copper, high silver brazing coil joint, high conductive efficiency.

Product parameters:

| Model | Rated power (KW) | Frequency(Hz) | Furnace capacity(T) | Input voltage (V) | Maximum current(A) | Transformer capacity(KVA) | Cooling Water Flow(t/h) |

|---|---|---|---|---|---|---|---|

| KGPS-250 | 250 | 1000 | 0.3 | 380 | 600 | 300 | 20 |

| KGPS-350 | 350 | 1000 | 0.5 | 380 | 900 | 400 | 20 |

| KGPS-500 | 500 | 1000 | 0.75 | 380 | 1200 | 600 | 25 |

| KGPS-750-1 | 750 | 1000 | 1 | 380 | 1500 | 800 | 30 |

| KGPS-750-0.7 | 750 | 700 | 1 | 660 | 1100 | 1000 | 40 |

| KGPS-1000 | 1000 | 700 | 1.5 | 660 | 1500 | 1500 | 50 |

| KGPS-1500 | 1500 | 500 | 2 | 660 | 1800 | 1800 | 60 |

| KGPS-2000 | 2000 | 500 | 2.5 | 950 | 1800 | 2500 | 70 |

| KGPS-3000 | 3000 | 500 | 3 | 950 | 2500 | 3150 | 80 |

| KGPS-4000 | 4000 | 500 | 5 | 950 | 3600 | 4000 | 100 |

| KGPS-4500 | 4500 | 500 | 6 | 950 | 4000 | 5000 | 120 |

| KGPS-6000 | 6000 | 500 | 8 | 950 | 2625*2 | 6300 | 150 |

| KGPS-8000 | 8000 | 300 | 10 | 950 | 3300*2 | 8000 | 160 |

| KGPS-9000 | 9000 | 300 | 12 | 950 | 1800*4 | 9000 | 180 |

| KGPS-10000 | 10000 | 300 | 15 | 950 | 2000*4 | 10000 | 200 |

| KGPS-12500 | 12500 | 300 | 20 | 950 | 2500*4 | 12500 | 240 |

| KGPS-15000 | 15000 | 300 | 25 | 950 | 3000*4 | 15000 |