Induction furnace producing process

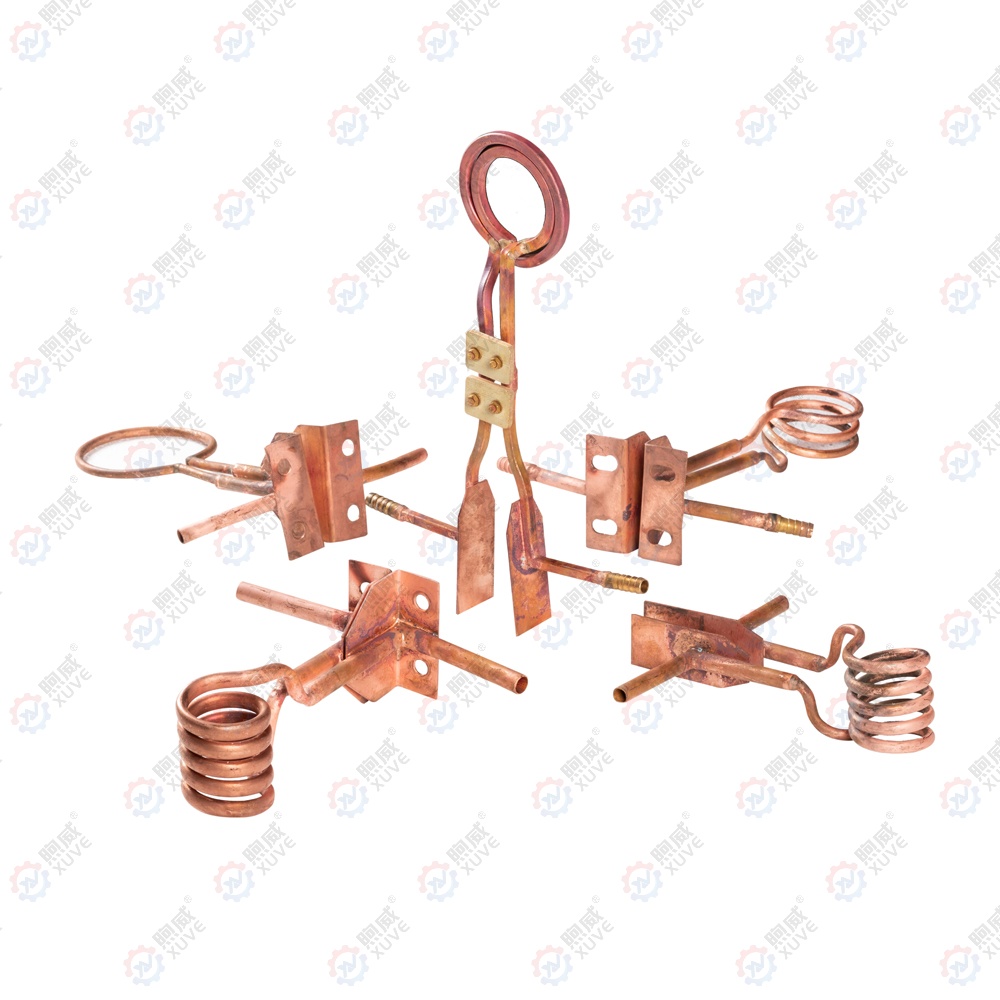

Engineer will design the inductor depending on the steel blank material, diameter, heating length, heating temperature and heating production per hour.Using high temperature and high voltage resistant insulation meterial to cover the copper tube and paint polyester red enamel before winding shape, refractory or concrete used to form the smooth and heat preservation inside tunnel which is durable.

Feature

1: Withstand high temperature and voltage,durable and safe

2: Calculation and designed by engineer team,ensure to get the maximum heating efficiency

3: Steel guide inside the furnace tunnel,feed the heating billet inside

4: Induction heating process for billet total heating or multi holes steel bar end heating

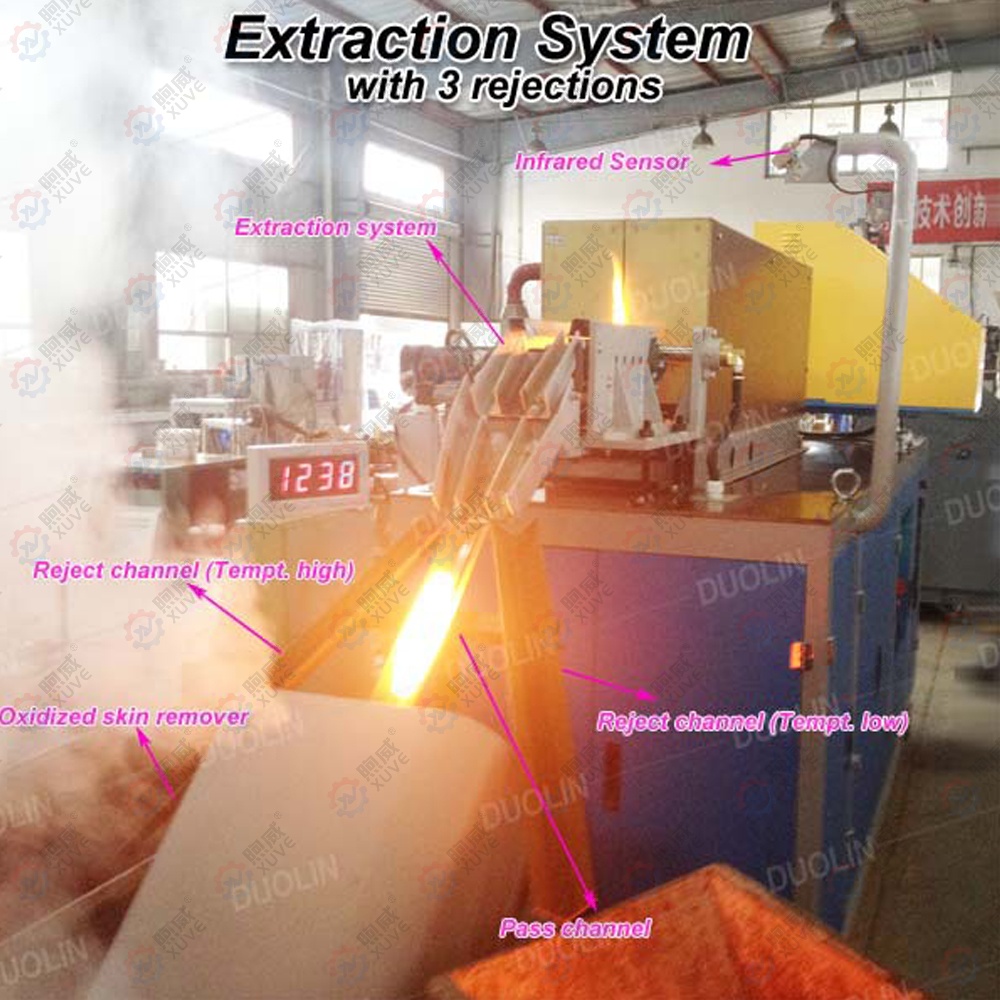

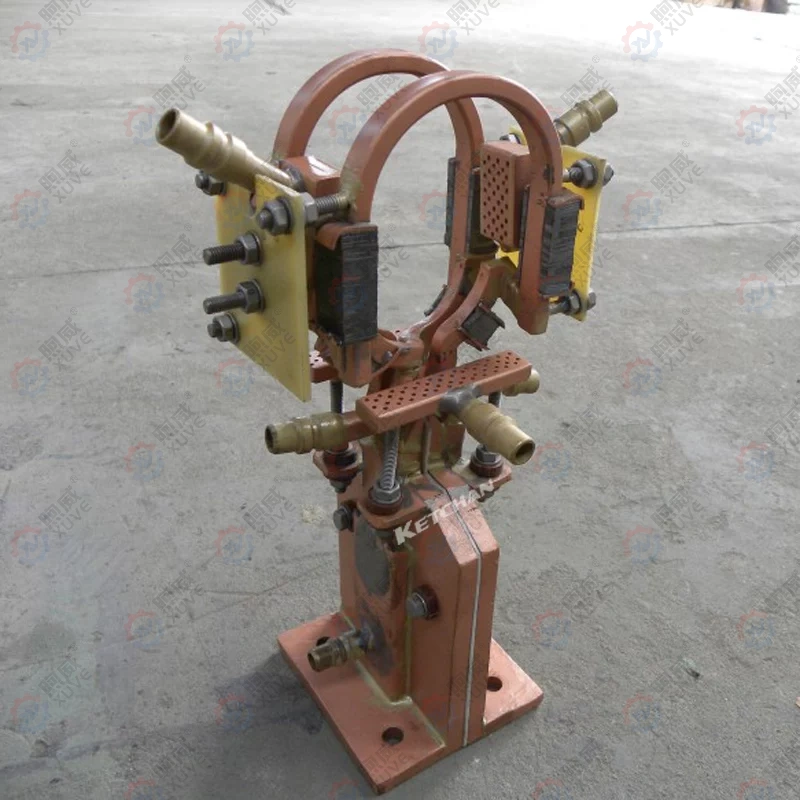

5: Pneumatic pusher and accept/reject delivery system as option

6: Cooling water pressure and temperature monitor