What is high frequency induction hardening machine?

A high-frequency induction hardening machine is mostly used for induction quenching industrial metal parts. It is a kind of metal surface induction heat treatment method that causes a certain induction electromotive force on the surface of the workpiece, rapidly warms the workpiece surface, and then rapidly heat treats the metal parts surface.

High frequency induction heat treatment machine heating hardening principle is: Place the workpiece into the induction coil which is wound with a copper tube. After entering high frequency AC, the workpiece surface generates the same frequency induction current. The workpiece surface can be heated quickly (within a few seconds can raise the temperature of 800 ~ 1000℃, the core is still close to the indoor temperature) and then quickly spray (dip) cooling water (or spray oil cooling) for induction quenching working, make the surface layer or part of the workpiece reach the required induction hardening depth and hardness.

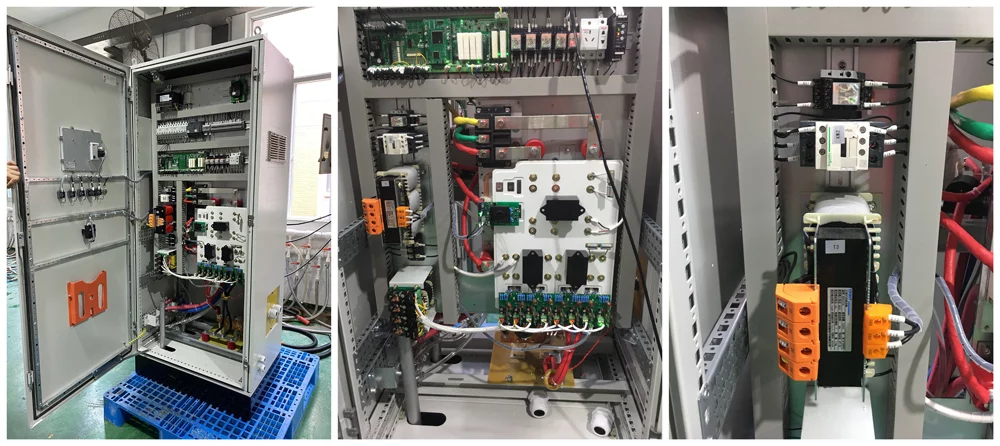

High Frequency Induction Hardening Machine Internal Details

What are high frequency induction hardening machine applications?

High frequency induction hardening machine is mainly used in the following workpieces induction heat treatment process:

- All kinds of steam and motorcycle with high-frequency quenching heat treatment, such as: crankshaft, connecting rod, piston pin, camshaft, valve, all kinds of gears in the gearbox, all kinds of forks, all kinds of spline shaft, transmission half shaft, all kinds of small shaft crank pin, all kinds of rocker arm, rocker arm shaft and other high-frequency induction quenching heat treatment.

- Hardware tools, such as vice, hammer, pliers, wrenches, high-frequency quenching heat treatment.

- Hydraulic components such as plunger pump plunger, rotor pump rotor, a variety of valves on the reversing shaft, gear pump gear, and other high-frequency quenching processes.

- High frequency quenching heat treatment for gear shaft of various power tools.

- All kinds of woodworking tools, such as ax, planers, and other parts induction heat treatment.

How to select a suitable high frequency induction hardening machine?

The high frequency induction hardening machine selection principle is: The less induction hardening depth, the higher the induction heating frequency should be. The more induction hardening depth requests, the lower the induction hardening frequency should be.

Normally hardening depth 0.2-0.8mm with frequency range 100-250KHZ, 1-1.5mm frequency range 40-80KHZ, 2-3mm frequency range 8-20KHZ, 3-5mm frequency range 4-8mm,5-8mm choose frequency range 0.5-4KHZ.

How can I get a faster quotation sheet?

In order to choose a suitable high frequency induction hardening machine, you can please let us know your hardening parts details, drawings along with induction hardening depth, and hardness will be appreciated.

Inventory Display of High Frequency Induction Hardening Machine