Summary

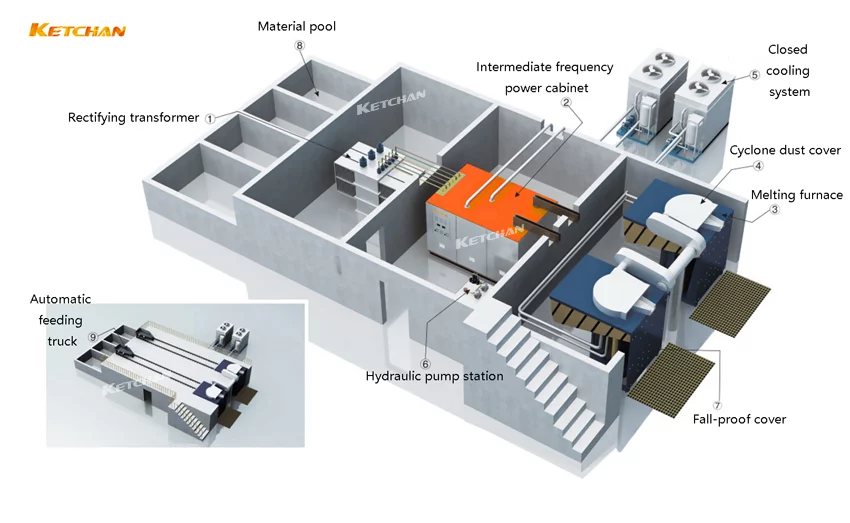

An intermediate frequency electric melting furnace is a frequency conversion device that converts three-phase power frequency current into single-phase intermediate frequency current. Through electromagnetic induction, the metal produces eddy current loss and achieves the induction heating and melting purpose. It is mainly for induction smelting and heating of ferrous or non-ferrous metals and alloys such as iron and steel, copper, and aluminum. Mainly used in metal casting and steel-making industry. ZHENGZHOU KETCHAN can provide foundry manufacturers with complete electric melting furnace production lines including an induction melting system, cooling system, dust removal system, automatic batching and pouring system.

Electric melting furnace technical suggestions

- ZHENGZHOU KETCHAN’s latest energy-saving “series intermediate frequency electric melting furnace” products, the power factor of the equipment is always in the highest state (≥96) than the ordinary parallel intermediate frequency furnace equipment to save about 20%, tons of molten iron power consumption of about 530 units electricity.

- We can provide foundry manufacturers with complete electric melting furnace equipment production lines including an induction melting system, cooling system, dust removal system, automatic batching and pouring system.

- Electric melting furnace diversity, different cost performance, so that you have more choices, more experience.

ZHENGZHOU KETCHAN electric melting furnace advantages

- Double power supply system: 1+2 series intermediate frequency electric melting furnace has a set of intermediate frequency power supply drag two furnace bodies work at the same time. (one set induction smelting furnace – one set temperature insulation furnace.)

- Advanced computer melting management system: The switch can be used to manage and control remote devices in the office, enabling remote device data collection, transmission, and monitoring, providing remote diagnosis and troubleshooting in a timely manner.

- Full digital electric melting furnace control system: automatic constant temperature, automatic furnace, power distribution display, intelligent melting management, fault information display and storage, and other automatic operations.

- Remote console: when the intermediate frequency electronic melting furnace power cabinet is placed in the basement, the remote operating table cloth is placed on the hearth, which can realize the other functions and operations such as starting, stopping, and resetting the intermediate frequency electric melting furnace power supply.

- Fault detection (protection) display: all-around real-time tracking and protection of running equipment, realizing automatic shutdown protection.

Electric melting furnace technical parameters

| Steel melting (1450℃) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity(t) | 0.5 | 1 | 1.5 | 2 | 3 | 4 | 5 | 7 | 10 | 12 | 15 | 20 | 30 |

| Power(kw) | 400 | 600 | 800 | 1000 | 1500 | 2000 | 2500 | 3000 | 5000 | 6000 | 8000 | 15000 | 20000 |

| Frequency(Hz) | 500 | 500 | 500 | 500 | 500 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

| Melting rate(t/h) | 0.6 | 1.08 | 1.4 | 1.89 | 2.94 | 3.78 | 4.62 | 5.67 | 9.76 | 11.76 | 16 | 30 | 40 |

| Melting consumption(kwh/t) | 525 | 525 | 525 | 520 | 520 | 510 | 500 | 500 | 490 | 490 | 500 | 500 | 500 |

| Cooling water flow(m³/h) | 5 | 7 | 10 | 13 | 18 | 25 | 30 | 34 | 55 | 62 | 72 | 92 | 100 |

| Aluminum melting(700℃) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Capacity(t) | 0.4 | 0.6 | 0.8 | 1.2 | 1.6 | 2 | 3 | 5 |

| Power(kw) | 200 | 300 | 400 | 600 | 800 | 1000 | 1500 | 2500 |

| Frequency(Hz) | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| Melting rate(t/h) | 0.38 | 0.63 | 0.74 | 1.10 | 1.57 | 1.94 | 2.94 | 4.83 |

| Melting consumption(kwh/t) | 525 | 525 | 525 | 520 | 520 | 500 | 500 | 500 |

| Cooling water flow(m³/h) | 5 | 8 | 9 | 12 | 15 | 20 | 26 | 45 |

| Copper melting(1250℃)) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Capacity(t) | 0.5 | 1 | 2 | 3 | 5 | 7 | 10 | 20 |

| Power(kw) | 300 | 500 | 1000 | 1500 | 2500 | 3000 | 5000 | 7000 |

| Frequency(Hz) | 500 | 500 | 500 | 500 | 250 | 250 | 250 | 250 |

| Melting rate(t/h) | 0.53 | 1.16 | 2.31 | 3.57 | 5.75 | 6.86 | 12.7 | 18.5 |

| Melting consumption(kwh/t) | 425 | 420 | 410 | 400 | 390 | 390 | 380 | 378 |

| Cooling water flow(m³/h) | 9 | 12 | 20 | 28 | 18 | 60 | 85 | 100 |