Equipment

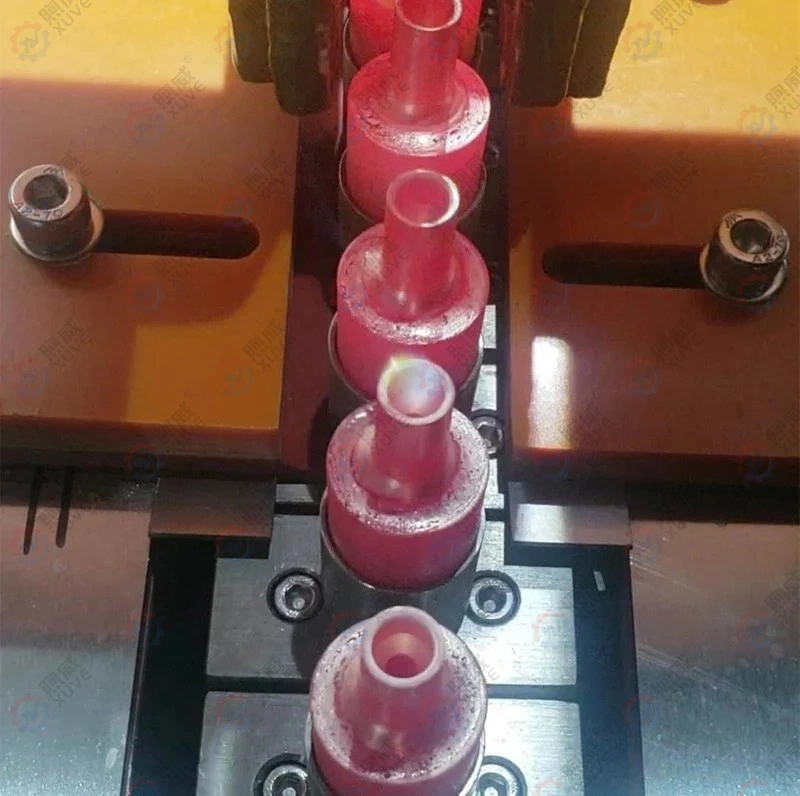

High frequency induction aluminum induction brazing machine.

Benefits

Due to the particularity of high-frequency welding of aluminum, we have designed a special power supply for high-frequency brazing of aluminum. It is designed to improve the success rate and pass rate of aluminum metal high frequency welding. The high-frequency aluminum welding machine power supply has higher control accuracy, and the power output fluctuation can be stably controlled at 3/1000, which is especially suitable for thin-walled parts or workpieces that are sensitive to temperature. In order to improve the heating accuracy, we also specially customized the machined induction brazing tool to help improve the heating accuracy of the whole aluminum induction brazing system.

Technical Parameters

| Name | High frequency aluminum induction brazing machine |

| Control mode | DSP digital controlled |

| Working model | Manual, automatic, temperature controller |

| Number of heating current setting segments | 5-32 pieces |

| Workpiece parameter storage Settings | 10 pieces |

| Working status display content | Time, current, frequency, current time curve |

| Alarm interface | Lack water, over current, over voltage, lack phase, overload. |

| Output power | 15KW~40KW |

| Output frequency | 10-60khz |

| Input voltage | 380V±10% 50/60Hz |

Automation choice

High frequency induction brazing machine, because of its uniform brazing result, clean working environment, and lower cost. It is widely used in automatic induction brazing systems. According to the user’s brazing parts details, we can design and do different automation level aluminum brazing systems. Zhengzhou KETCHAN technical team is expecting to hear your news for sharing more.

Applications

Aluminum induction brazing machine is mostly used for induction brazing of automotive evaporator aluminum tubes, induction brazing of aluminum distributors, aluminum plates, aluminum tubings, aluminum pipes, aluminum fittings, etc.