What are KETCHAN induction rod forging furnace features?

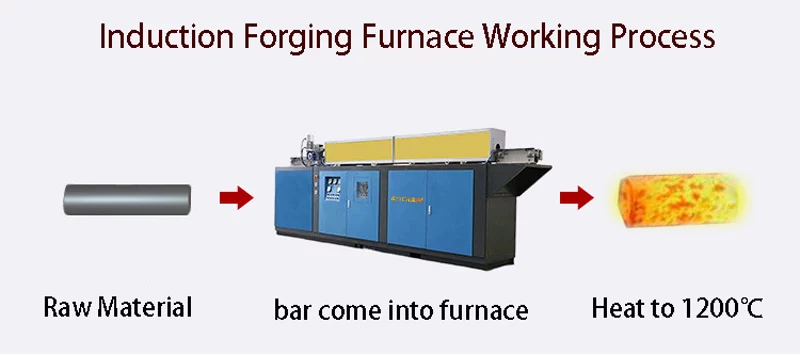

- Ketchan induction rod forging furnace is mainly used for all kinds of different workpiece heating jobs, the heating temperature is between 200-1800℃.

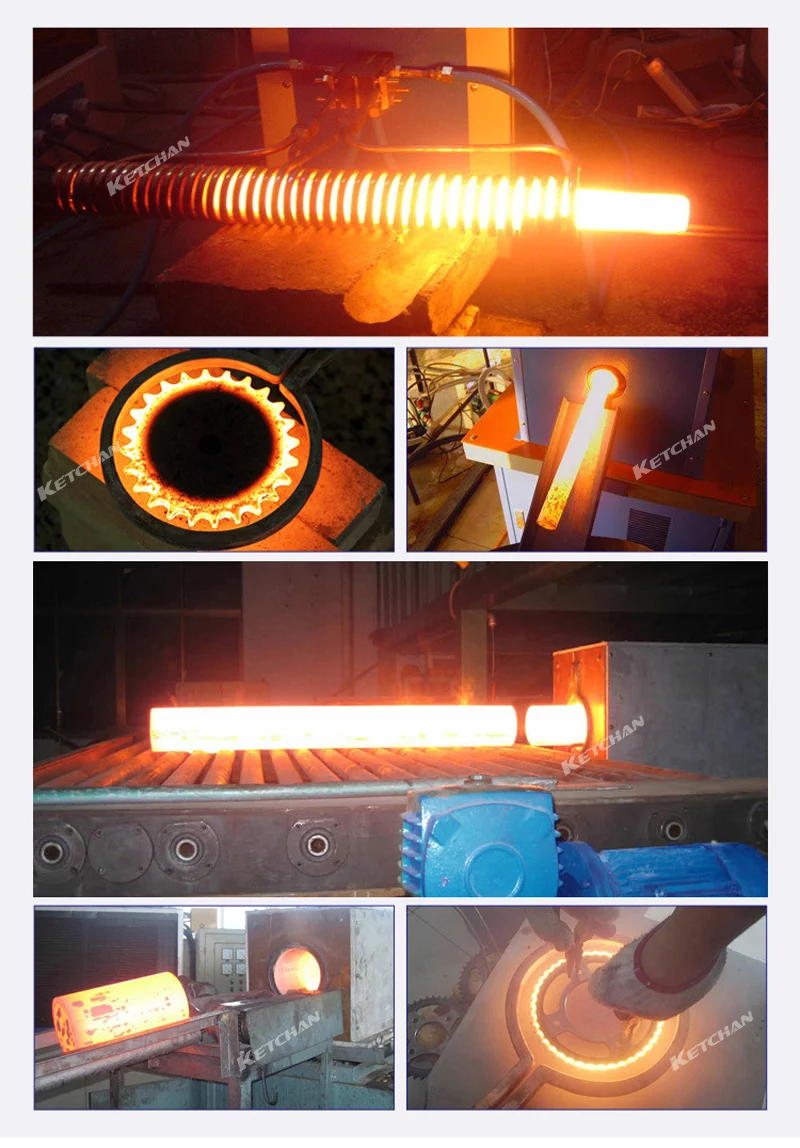

- Before forging induction heating: Mainly used for gears, ring gears, bearings, shackle, rigging induction heating forging.

- Online induction heating: Used for pipeline anticorrosive coating, long steel bar induction heating forging, steel wire, and steel pipe online induction hardening tempering process.

- Local induction heating: U shape bolt heating bending, drum thermal assembly, steel tube steel elbow induction heating forging process.

What are KETCHAN induction rod forging furnace technical advantages?

- Ketchan induction rod forging furnace is with fast heating speed, high production efficiency, less oxidation, and decarbonization, saving a lot of materials and forging dies costs.

- Superior working environment, energy-saving, and pollution-free improve the company image.

- Uniform heating, small temperature difference, high precision temperature control.

- Energy-saving, low burning loss, easy to start.

- High stability, strong anti-interference ability, easy maintenance, and easy to upgrade.

Why is Choose KETCHAN induction rod forging furnace?

- Induction forging furnace:

- KETCHAN induction rod forging furnace induction coil is insulated by two kinds of high-temperature insulating paint and glass fiber tape winding. Have high stability, strong anti-interference ability, easy maintenance, easy to upgrade features.

- The top of the furnace is designed with a sliding cover for easy maintenance and inspection.

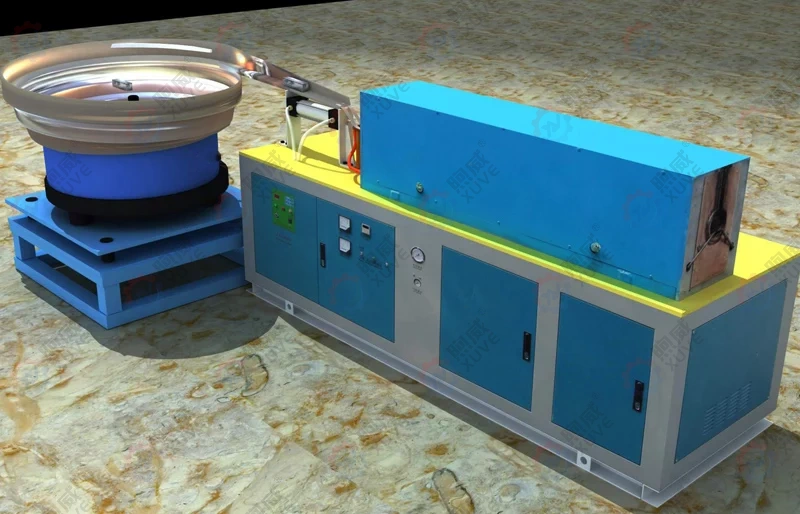

- Material Feeding Mechanism:

- The feeding system adopts clamp roller feeding, suitable for a bar diameter range of 40-120mm.

- The induction rod forging furnace feeding speed is controlled by a frequency conversion motor, and the feeding speed is adjustable.

- Pitch roller feeding motor, reducer adopts aluminum shell, can effectively prevent heat around the coil.

- Temperature Control System

- The induction rod forging furnace system can accurately control the temperature of the water outlet, and both inlet and outlet of the furnace body adopt a water-cooled copper plate.

- Furnace body cooling water pipe adopts high-temperature carbon-free hose, the service life of more than three years.

- Induction Forging Power Supply Control Cabinet

- The main control board of the cabinet is microcomputer controlled, and one key zero voltage start, plug, and work.

- The water pressure meter of the furnace body and the control cabinet adopts a separate design, which can monitor the water pressure of the control cabinet and the furnace body more conveniently and intuitively.