What is handheld induction brazing machine?

Handheld induction brazing machine is a series of portable induction heaters, which we did for induction brazing projects which are the complex and difficult to access to the workpiece or workshop locations.

When doing the induction brazing welding jobs, the brazed parts are placed in the alternating magnetic fields. The heating of the denominator is achieved by the resistive heat of the induced current it generates in an alternating magnetic field. The higher the frequency, the less the current penetrates, although the workpiece surface is rapidly heated, the heating thickness is thinner, the internal parts can only rely on the surface layer for internal heat conduction to heat, this is the skin effect.

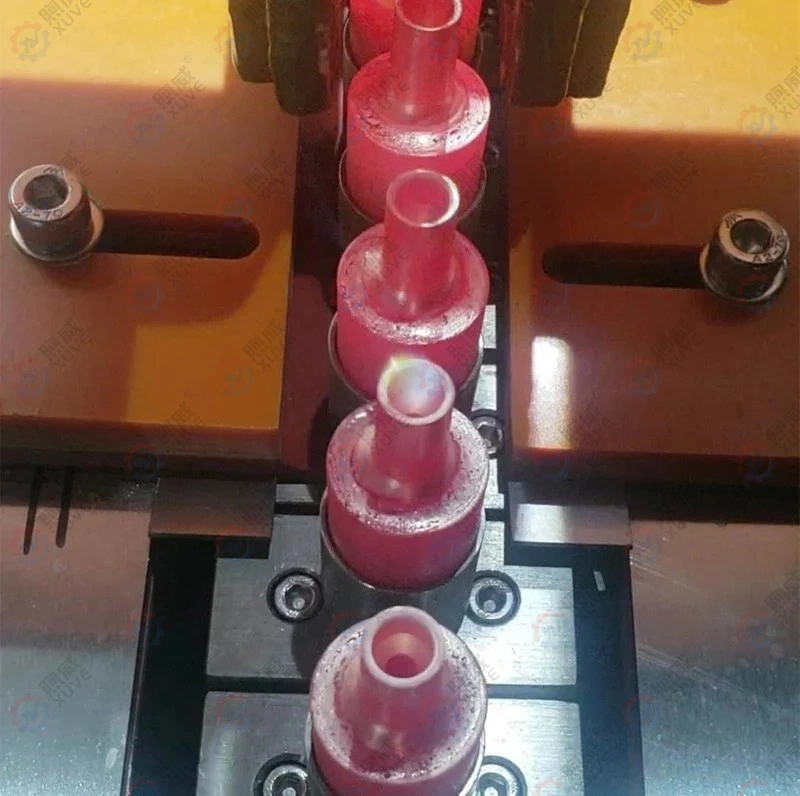

The induction coil is an important part of induction brazing equipment. The basic principle of correct design and selection of induction coil is: to ensure fast and uniform heating and high efficiency. Generally, the induction coil is made of a pure copper tube, which is cooled by water in the tube. The thickness of the tube wall should be less than the current penetration depth, which is generally 1~1.5mm. Thus, it can be seen that it is not advantageous to choose a high ac frequency, generally around 500kHz frequency is more appropriate. In addition, the skin effect is also related to the resistivity and permeability of the material, the greater the resistivity, the smaller the permeability, and the weaker the skin effect, on the contrary, the more significant the skin effect.

What is the difference between flame brazing and induction brazing?

| Contrast factor | Flame brazing | Induction brazing |

| Safety factor | A large number of waste gas generated in the flame welding process is harmful to human health, acetylene, liquefied gas storage, and transportation, there are potential safety hazards in use, inflammable and explosive. | Electric, safe and reliable, replacing flame welding, eliminating the liquid gas storage, transportation, and use, and removing hidden dangers at all levels. |

| Energy-saving, good environment | The open flame welding process will produce a lot of carbon monoxide, carbon dioxide, and other toxic gases, gas waste. | Since it uses electricity, the working environment is very clean compared to acetylene, gasoline, oxygen, LPG, and other gases, and the cost is greatly reduced. |

| High efficiency | Traditional flame welding temperature is not uniform, high thermal radiation, welding cost is high, there is explosion risk, and welding temperature is only controlled by personal experience. | Uniform induction brazing welding, good penetration, and strong versatility, through the handheld induction brazing machine conversion function, can achieve a perfect combination of copper pipe, copper steel pipe, steel pipe welding, and strong versatility. |

| Labor cost |

High requirements for welding workers’ skills, and welding is not easy to master. |

The training is simple, the welding method is simple to master, and the skill requirement for welding workers is low. Ordinary workers can weld correctly after simple training and a short time of practice. |

| Material cost | Welding cost is high, soldering flux is out of control, and solder consumption is based on personal experience. | Using brazing rings, the cost can be controlled, save solder, and flux, and avoid artificial waste of material, flux, avoid artificial waste. |

What is Xuve Electronic handheld induction brazing machine features?

Handheld induction brazing machine has the advantages of convenient movement, strong controllability, precise operation, and low cost.

- Easy to move: The handheld induction brazing machine can realize induction brazing for complex and inaccessible workpieces or workshop locations, with small physical examination, convenient movement, and simple operation.

- Strong controllability: the controllability and accurate heat transfer of induction heating reduce the risk of overheating to the greatest extent, thus avoiding the workpiece heat loss.

- Precise operation: High frequency, stable heating output, no vibration during working heating, ensure accurate welding position, can weld the minimum diameter of 0.1mm capillary metal, and can customize different induction coils according to the workpiece’s different shapes.

- Ease of operation: There is no need to transport or store batches of workpieces near the handheld induction brazing equipment during brazing, making it ideal for in-line induction brazing.

- Reduced costs: Efficient and precise heating processes ensure solder yields, minimizing scrap, rework, and energy consumption.

- Efficient working environment: Induction heating is quiet and comfortable, and does not cause the surrounding environment to heat up.