What is slewing ring induction hardening machine?

Slewing ring channel hardening and tooth hardening: In the production process of slewing bearing, surface hardening is adopted on the bearing ring raceway and tooth surface. Surface hardening is a combination of heating and immediate cooling. The surface of the machined steel is heated to the quenching temperature by rapid heating and cooled rapidly before the heat is transferred to the center of the slewing rings, resulting in a surface hardening layer with only martensite hardened on the surface and unhardened original normalizing or tempering structure in the center. With slewing ring induction hardening machine, General tooth surface hardening hardness HRC45-55; Raceway hardening hardness HRC50-60. Hardness is related to the induction heat treatment level and then affects the service life.

Tempering stability: After the slewing ring induction machine finishes the hardening process, hardness is high, and brittleness is bigger. It is easy to crack or brittle break in subsequent processing and use.

Subsequent processing and use of easy to crack or brittle break, through tempering stability can reduce internal stress to prevent late processing deformation, reduce brittleness, and improve toughness. The stability of induction tempering can reduce internal stress, prevent deformation, reduce brittleness and improve toughness.

What is slewing ring induction hardening machine application?

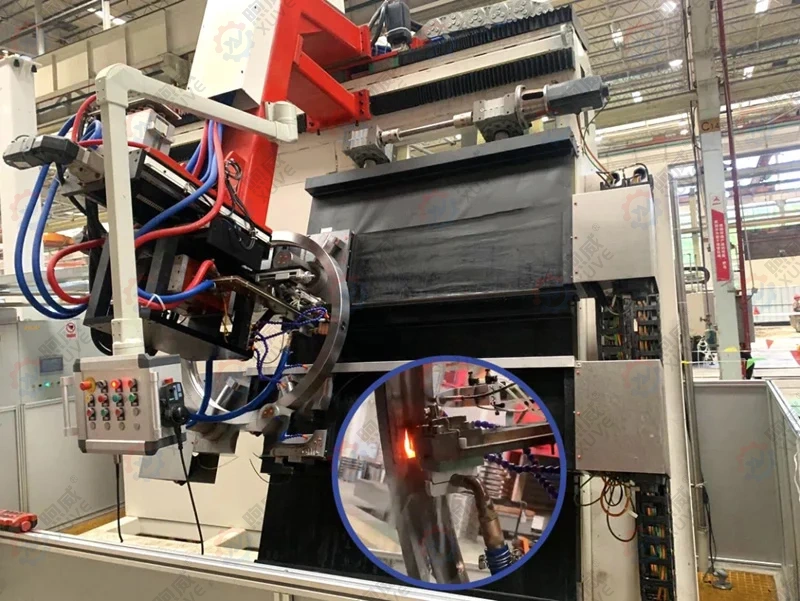

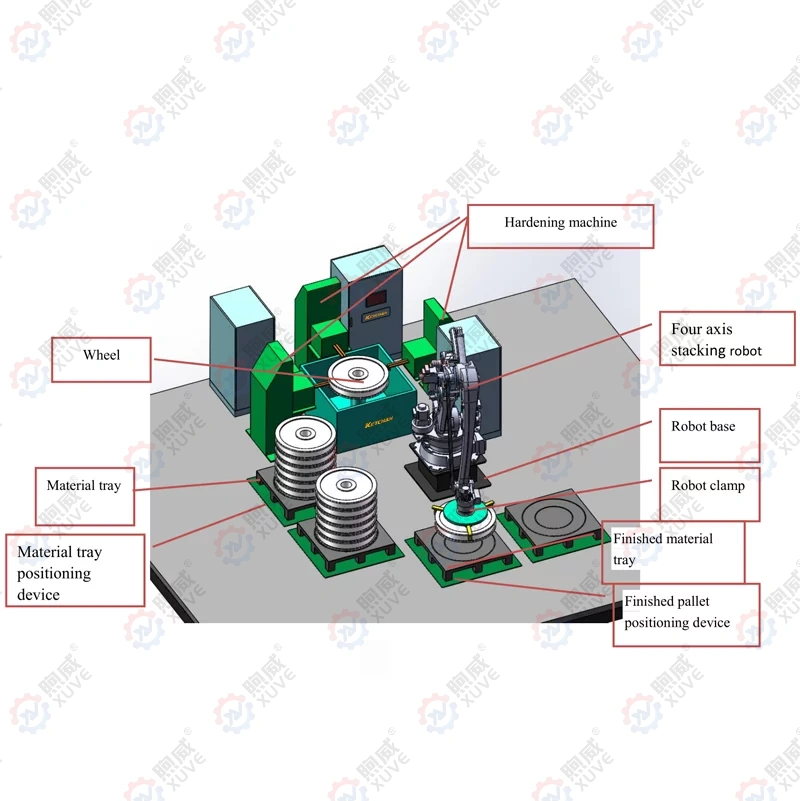

Zhengzhou KETCHAN Electronics Co., Ltd. specializes in the production of gear, slewing rings raceway CNC induction hardening machines. This slewing rings induction hardening machine has the functions of inductor ascending and descending movement, advance and retreat movement, lateral movement, parts rotation, and so on.

KETCHAN’s slewing ring induction hardening machine is mainly used for rotary scanning quenching of big gear inner and outer teeth, big sprocket, single tooth hardening, integral quenching, slewing bearing, rotary bearing, wind power bearing, raceway, gear ring, steel collar, track, excavator slewing bearing, crane inner gear and so on.

How to do slewing ring induction hardening?

- Our slewing ring induction hardening machine can process slewing ring maximum diameter range of hardening part:300—5000mm,maximum height:400mm and a maximum weight of hardening parts:500Kg

- According to the technical requirements of slewing bearing induction hardening, the CNC induction hardening machine adopts the structure of transformer lifting and moving, radial feeding and transverse moving, and the rotary table is driven by a servo motor to rotate, which can realize the functions of gear automatic indexing and raceway continuous scanning quenching. The machine tool has good versatility.

- The complete slewing ring induction hardening machine induction heating power supply part adopts 200Kw/ 4-10khz parallel resonant full digital IGBT transistor power supply, equipped with a set of induction heating load, can be used with different structure induction hardening coil, through load matching adjustment, to achieve the best heating effect.

- Equipped with a set of induction heating load monitoring systems, which can display, record, and store the main process parameters.

- Air cooler type industrial water chiller (or closed air cooler) for softening water circulation cooling; Softening water circulation cooling system is used for cooling power supply, quenching transformer, inductor, etc., and provides secondary cooling water for quenching medium; The quenching medium circulation cooling system is cooled by water – water convection through the plate heat exchanger.

What are slewing ring induction hardening machine features?

- According to the bearing ring internal and external teeth and raceway induction quenching process requirements, This CNC hardening machine tool is equipped with an induction heating load. Adopt transformer/inductor synchronous lifting and moving, single radial moving, parts indexing rotation structure. This bearing ring induction hardening machine can meet the diameter below 5000mm bearing rings inner and outer raceway scanning induction quenching, large modulus gears single tooth induction hardening requests.

- It has the function of changing power and moving speed during the quenching process.

- The bearing ring induction hardening machine control system adopts a PLC+ touch screen control system, the quenching process program can be input, modified, and stored through the keyboard, quenching process program can be automatically controlled.

- The indexing rotation of parts is driven by a servo motor, and accurate indexing control is realized by a NUMERICAL control system.

| No. | Item | Unit | Data |

| 1 | Rotary diameter range of hardened parts | mm | 300—2100 |

| 2 | Maximum height of hardened parts | mm | 350 |

| 3 | Maximum weight of hardened parts | Kg | 2000 |

| 4 | Transformer lifting and moving stroke | mm | 450 |

| 5 | Transformer radial travel distance | mm | 700 |

| 6 | Transformer up and down moving speed | mm/s | 2~60 |

| 7 | Transformer horizontal adjustment distance | mm | ±50 |

| 8 | Transformer lifting, moving, and repeated positioning accuracy | mm | ±0.05 |

| 9 | Transformer radial moving repeat positioning accuracy | mm | ±0.05 |

| 10 | Dividing way | Auto | |

| 11 | Cooling method | Spraying liquid | |

| 12 | CNC induction machine tool control | PLC+Touch Screen |